High Level Palletizers

All Columbia high level models include our industry-leading Category 3 safety package and are available in endless layout configurations.

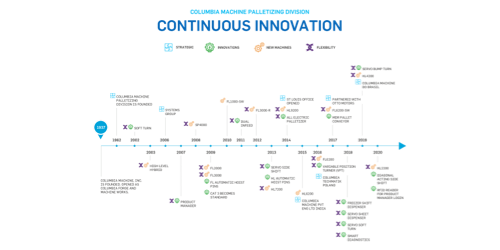

Innovation driven by:

Why Choose a High Level Palletizer?

High level infeed conventional palletizers are generally faster and have a comparatively smaller footprint than floor level palletizers. Additionally, more efficient traffic flow can be realized in plants when there are multiple palletizers in one area or the palletizing process is located a significant distance from the packaging area.

With Columbia’s advanced Product Manager graphic-based HMI, our conventional palletizers offer unlimited pattern-forming capabilities and zero time — zero tool changeover. As an integrated systems solutions provider and home to the broadest palletizer product line of any conventional palletizer supplier, Columbia is sure to have a solution for all of your palletizing needs.

High Level Palletizer FAQs

Package / product infeed elevation is usually between 110" and 145" above the floor for a High Level palletizer. Complete loads of product are built by forming rows of product which become complete layers. A chain driven hoist is located in the load building area to bring an empty pallet up to the layer stripper apron and be in position to accept the first layer of a new load. The hoist raises and lowers accepting new layers of product until the desired number of layers has been placed on the pallet to form a complete load.

High Level Infeed palletizers are generally faster than a comparable size floor level palletizer. The smaller footprint and elevated infeed are ideal when multiple palletizers are placed in an area where access is needed both upstream and downstream of the palletizing process.

Most High Level infeed palletizers bring product into the machine at roughly 110" to 145". Specific patterns are created by orienting packages to form rows of product. The rows of product are combined to form complete layers of product in a specific predetermined pattern. Complete loads are built by placing the desired number of layers on top of one another.

Palletizer sizing is a function of desired production rate (cases per minute), layer patterns and machine and facility layout.

Automating the end of a production line is a necessity when the rate is too high for workers to safely build loads of finished goods by hand. when the finished load is somewhat tall (above shoulder height) or if there is a risk to injury due to repetitive motion activity.

Maintenance requirements are very low but will vary by application to some degree. Operations that are somewhat dusty or that run 3 shifts per day and 7 days a week will require more frequent maintenance. Typical annual maintenance may include conveyor drive belt replacement or perhaps a cylinder seal or a sensor replacement.

All Columbia Palletizers include Category III safety components and wiring methodology.

All Columbia palletizers use standard components that are customized to meet the unique needs of every application. Working with our Sales Engineering team to optimize the plant layout, machine orientation and package handling variables will ensure your palletizing solution is optimized. With the boadest line of conventional palletizers available, Columbia can always size the palletizer for current needs as well as considering potential future needs.

All Columbia palletizers use standard components that are custom configured to meet the unique needs of every application. There are countless layout configurations available, slip and tier sheet options, touchless case turning infeeds, small case handling kits and more.

Most High Level palletizers are used when the space allowed combined with the desired production rate is not suitable for a Floor Level palletizer. If the palletizing process is located a considerable distance from the upstream packaging process, the case conveyor line feeding the palletizer will almost certainly be elevated to transport the product to the palletizer. Once up in the air (between 110" and 145") there is no point in bringing the product back down when High Level palletizers exist and do a great job.

Columbia's High Level Palletizers Set The Industry Standard

Each of these modular machines can be upgraded to grow with your business, while versatile interfaces allow for seamless integration with your production equipment.

Free Science Of Palletizing Book

Request your free copy of The Science of Palletizing Book. The Science of Palletizing is a 72-page educational introduction to the basics of unit-load forming and is designed to familiarize you with the fundamentals of palletizing.