Complete Palletizing Solutions

Columbia manufactures inline high speed, high level, floor level and robotic hybrid palletizers, load transfer stations and provides complete system integration.

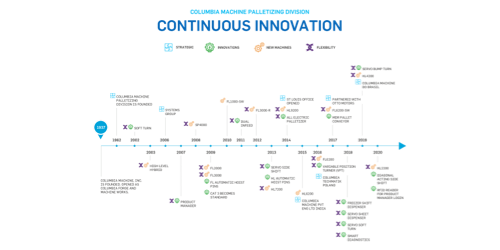

Innovation Timeline

Discover how innovation driven by safety, flexibility and performance has propelled Columbia Machine to become the industry leader in palletizing solutions.

Load Transfer Stations

Learn how to easily transfer your pallet load from one pallet type to another pallet type.

Customer Care

It’s our mission to keep your plant running at peak performance.

Explore Our Palletizer Solutions

Columbia Machine manufactures high level, floor level and robotic palletizers; load transfer stations and provides complete system integration. All equipment is built with the highest priority on safety, flexibility, performance and support to ensure your palletizer maximizes production every day, for the life of your palletizer.

Floor Level Palletizers

Columbia's conventional floor level palletizer machines are designed to fit your operation and production needs. The easy access offered by the floor level infeed, the standard category 3 safety features and the easy-to-operate Product Manager software package are unmatched in the industry.

More InformationHigh Level Palletizers

Columbia's conventional high level palletizer machines set the industry standard. Each of these palletizing machines can be upgraded as your business needs change, while adaptable interfaces allow for smooth integration with your production equipment.

More InformationHigh Speed Inline Palletizers

Columbia's conventional inline palletizer machines use a continuous motion flow divider that position the product into the accurate position on the layer forming area until a layer is complete and placed onto the pallet. They are ideal for medium to high speed plants and multiline applications.

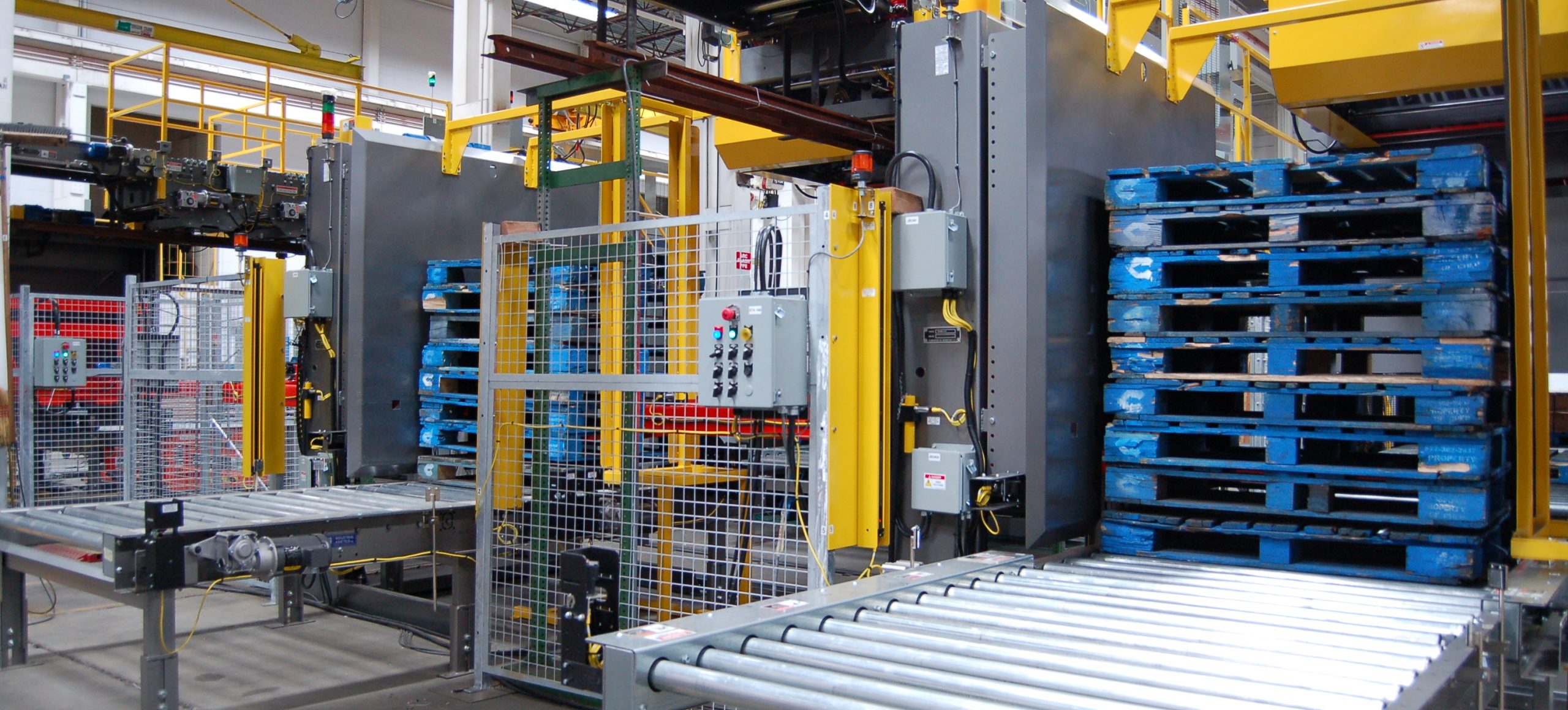

More InformationLoad Transfer Stations

The Load Transfer Station (LTS) transfers product from one pallet type to another type including wood to in-house “clean” pallets, plastic to wood, or other combinations. This transfer process can assist your plant with meeting FSMA, HACCP & GMP requirements.

More InformationSystem Integration

To ensure your Columbia palletizer fits perfectly with your upstream and downstream production equipment, Columbia provides complete system integration services. Complete system integration includes concept, design, integration and installation.

Accessories

Columbia’s palletizing solutions are always customized to meet the unique needs of every customer’s application. We have a wide array of options and features available to ensure your system is optimized for your known applications today and unknown needs for tomorrow.

Automatic Palletizer Machines

With the most extensive palletizer line, Columbia Machine is able to meet the palletizing needs of most industries including food, beverage, dairy, paper, personal care, chemical, pharmaceutical and building products. A Columbia palletizer machine can handle your specific product mix with proven modular components that can be placed on most all models to gently and efficiently stack your package type.

Why Choose a Conventional Automated Palletizer?

Columbia Machine provides the most innovative and flexible palletizing solutions available. Columbia conventional palletizers handle virtually any package type including trays (wrapped or unwrapped), shrink-only bundles, RPCs, Totes, tab-lock cases, milk crates and so much more.

With Columbia’s advanced Product Manager graphic-based HMI, our conventional palletizers offer unlimited pattern-forming capabilities and zero time — zero tool changeover. As an integrated systems solutions provider and home to the broadest palletizer product line of any conventional palletizer supplier, Columbia is sure to have a solution for all of your palletizing needs.

We’re Ready To Help

For more information or questions about our complete line of palletizing solutions

Free Science Of Palletizing Book

Request your free copy of The Science of Palletizing Book. The Science of Palletizing is a 72-page educational introduction to the basics of unit-load forming and is designed to familiarize you with the fundamentals of palletizing.