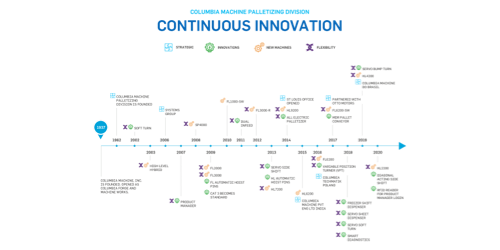

LTS-C

Fork truck driver places the "go to" pallet onto a pallet cart, allowing the transfer process to complete automatically.

LTS-C Transferring Glass Vials

LTS with pallet cart (LTS-C) transferring glass vials from wood to plastic pallets.

LTS-C

LTS with pallet cart (LTS-C) transferring from CHEP to plastic pallet.

Increase Forklift Efficiency

The Load Transfer Station with Pallet Cart is a standard LTS with the addition of a pallet cart. The forklift driver places the "go to" pallet on the pallet cart, and then activates the machine via the pull cord to extend the receiving deck. The unit load is placed on the receiving deck and the driver activates the transfer process allowing the transfer to automatically complete. The LTS has an internal upstacker with a 15 pallet storage capacity.

Safety And Efficiency Are Our Top Priorities

We design our Load Transfer Stations with safety and efficiency as our top priorities. Each of our LTS models allows the operator to stay in the forklift during machine operation, eliminating the need for manual pallet handling.

What Is A Load Transfer Station?

Load Transfer Stations are capable of transferring products that are packaged in cases, barrels, drums, bags and pails from one pallet to another including Plastic, Chep and GMA pallets in both receiving and shipping applications. Columbia's Load Transfer Stations (LTS) optimizes your facility's lift truck productivity, reduces labor and shipping costs, prevents contamination from entering production areas AND prevents injuries. Load Transfer Stations have proven to be safer & faster than load inverters.