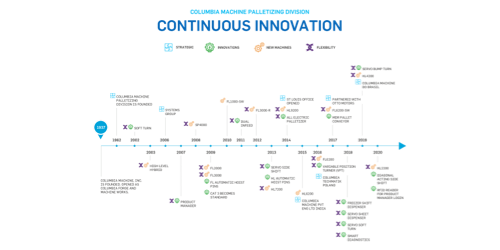

Columbia Machine Palletizing Division

Continuous Innovation

-

Strategic

-

Innovations

-

New Machines

-

Flexibility

Columbia Machine Inc. Is founded. Opened As Columbia Forge And Machine Works

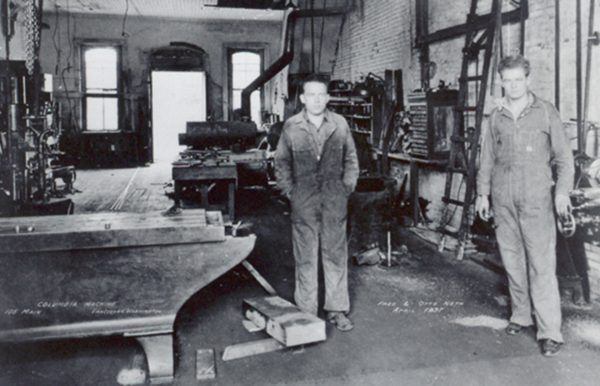

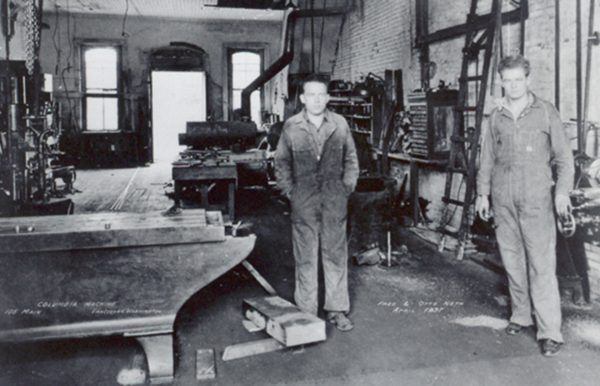

In 1937, Fred Neth Sr. took out a small loan to establish Columbia Forge and Machine Works in Vancouver WA. Columbia Machine, Inc. as it is known today, is still owned and managed by members of the Neth family. From humble beginnings, Columbia now employs roughly 500 people at our headquarters in Vancouver WA, has manufacturing facilities on four continents and employs over 1,000 people worldwide.

Columbia Machine Inc. Is founded. Opened As Columbia Forge And Machine Works

In 1937, Fred Neth Sr. took out a small loan to establish Columbia Forge and Machine Works in Vancouver WA. Columbia Machine, Inc. as it is known today, is still owned and managed by members of the Neth family. From humble beginnings, Columbia now employs roughly 500 people at our headquarters in Vancouver WA, has manufacturing facilities o...

Columbia Machine Palletizing Division Is Founded

In 1963, Columbia leveraged the knowledge of building load handling equipment from our Concrete Products Division and built our first palletizer for a local brewer of Lucky Lager. That was almost 60 years and roughly 4,000 palletizers ago!

Columbia Machine Palletizing Division Is Founded

In 1963, Columbia leveraged the knowledge of building load handling equipment from our Concrete Products Division and built our first palletizer for a local brewer of Lucky Lager. That was almost 60 years and roughly 4,000 palletizers ago!

Load Transfer Stations

Columbia's Load Transfer Stations (LTS) offer a seamless solution for transferring palletized products such as cases, barrels, drums, bags, and pails between different pallet types, including Plastic, Chep, and GMA pallets, for both receiving and shipping operations. Columbia’s LTS systems even support transfers from pallets to slip sheets, enhancing operational flexibility.

Load Transfer Stations

Columbia's Load Transfer Stations (LTS) offer a seamless solution for transferring palletized products such as cases, barrels, drums, bags, and pails between different pallet types, including Plastic, Chep, and GMA pallets, for both receiving and shipping operations. Columbia’s LTS systems even support transfers from pallets to slip sheet...

Soft Turn

Columbia started building the touchless turning Soft Turn unit almost 20 years ago. Columbia has supplied roughly 400 of these units and even retrofitted the Soft Turn on to competitors’ existing palletizers! The updated version allows for smaller gaps between packages leading to increased palletizer throughput. Other enhancements have made the Soft Turn more flexible and able to handle smaller packages with ease.

Soft Turn

Columbia started building the touchless turning Soft Turn unit almost 20 years ago. Columbia has supplied roughly 400 of these units and even retrofitted the Soft Turn on to competitors’ existing palletizers! The updated version allows for smaller gaps between packages leading to increased palletizer throughput. Other enhancements have ...

High Level Hybrid

Hybrid palletizers are a niche segment in material handling that combines the specific functionality of a robotic arm with the simple and robust layer forming capacity of a conventional palletizer. Although somewhat limited in scope, there are a few applications where combining the best of both worlds results in a fantastic solution.

High Level Hybrid

Hybrid palletizers are a niche segment in material handling that combines the specific functionality of a robotic arm with the simple and robust layer forming capacity of a conventional palletizer. Although somewhat limited in scope, there are a few applications where combining the best of both worlds results in a fantastic solution.

Systems Group

In 2006, Columbia became a full systems integrator. As the internal engineering resources at customer facilities were being reduced, customers were reaching out and asking Columbia to take on complete system responsibility and provide fully integrated palletizing solutions, not just machines. Today, the Integrated Systems Group at Columbia is a very significant and growing part of our business, providing complete systems design, engineering, and mechanical and electrical installation.

Systems Group

In 2006, Columbia became a full systems integrator. As the internal engineering resources at customer facilities were being reduced, customers were reaching out and asking Columbia to take on complete system responsibility and provide fully integrated palletizing solutions, not just machines. Today, the Integrated Systems Group at Columbia...

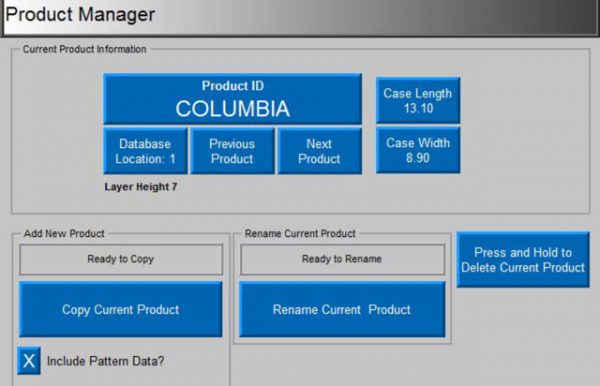

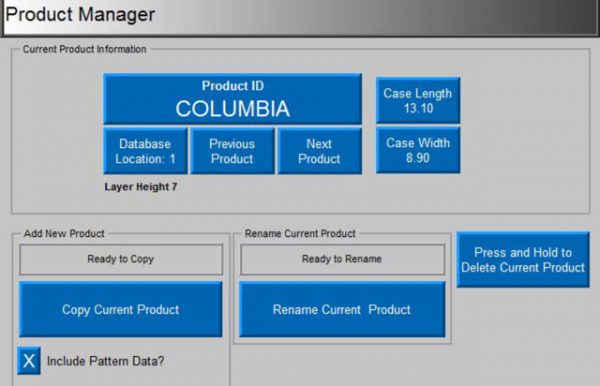

Product Manager

Columbia’s Product Manager graphic HMI interface provides incredible flexibility for current and future palletizing needs. Simply from the HMI, users can add or adjust existing patterns, adjust timer delays and VFD speeds, view production reports, access machine I/O status and so much more. All of this is possible without the need to connect a computer to the PLC.

Product Manager

Columbia’s Product Manager graphic HMI interface provides incredible flexibility for current and future palletizing needs. Simply from the HMI, users can add or adjust existing patterns, adjust timer delays and VFD speeds, view production reports, access machine I/O status and so much more. All of this is possible without the need to co...

SP4000

The SP4000 high level palletizer has been updated in Columbia’s product line and was replaced by the HL4200 in 2019.

SP4000

The SP4000 high level palletizer has been updated in Columbia’s product line and was replaced by the HL4200 in 2019.

FL2000

The FL2000 floor level palletizer is flexible, energy efficient, loaded with safety features and EASY: easy to install, easy to operate, easy to maintain, easy to adjust and flexible for tomorrow’s unknown packaging challenges. Requiring no modification, the FL2000 can handle a wide variety of package types including cases, trays, totes, film only bundles and display packs from a variety of industries. The FL2000 palletizes 20 cases per minute or more, depending on case size and pallet pattern.

FL2000

The FL2000 floor level palletizer is flexible, energy efficient, loaded with safety features and EASY: easy to install, easy to operate, easy to maintain, easy to adjust and flexible for tomorrow’s unknown packaging challenges. Requiring no modification, the FL2000 can handle a wide variety of package types including cases, trays, totes, ...

FL3000

The FL3000 floor level palletizer provides the ultimate combination of safety, performance and flexibility to handle a wide variety of package types including cases, display packs, totes, trays, bundles, shrink film without pad, bales, plastic containers, crates, small cases and more. The FL3000 is able to obtain greater speeds due to the addition of a layer storage table, palletizing at 20 – 55 cases per minute, depending on case size and pallet pattern.

FL3000

The FL3000 floor level palletizer provides the ultimate combination of safety, performance and flexibility to handle a wide variety of package types including cases, display packs, totes, trays, bundles, shrink film without pad, bales, plastic containers, crates, small cases and more. The FL3000 is able to obtain greater speeds due to the a...

FL Automatic Hoist Pins

All Columbia palletizers come with automatic hoist protection pins. Previously available as an option, the pneumatically retained, spring actuated pins engage in staggered slots that are part of the palletizer frame when air pressure is removed from the palletizer.

FL Automatic Hoist Pins

All Columbia palletizers come with automatic hoist protection pins. Previously available as an option, the pneumatically retained, spring actuated pins engage in staggered slots that are part of the palletizer frame when air pressure is removed from the palletizer.

CAT 3 Becomes Standard

Cat 3 safety content is standard on the entire Columbia Machine Palletizer product line. Columbia’s standard Cat 3 components include Fortress trapped keys for machine access on HL palletizers, Allen-Bradley SensaGuard RFID interlocked safety switches for FL palletizers and full height Banner light curtains on palletizer discharge areas and other protected zones, as needed. Other brands may be substituted if required and Cat 4 is available as an option.

CAT 3 Becomes Standard

Cat 3 safety content is standard on the entire Columbia Machine Palletizer product line. Columbia’s standard Cat 3 components include Fortress trapped keys for machine access on HL palletizers, Allen-Bradley SensaGuard RFID interlocked safety switches for FL palletizers and full height Banner light curtains on palletizer discharge areas...

FL1000-SW

The FL1000 floor level palletizer provides an optimal price and speed combination for low speed applications. The FL1000’s compact footprint utilizes less than 60 square feet of floor space. Requiring no modification, the FL1000 can handle a wide variety of package types, including cases, trays, totes, film only and display packs from a variety of industries. The FL1000SW includes a fully integrated stretch wrapper for “stack-n-wrap” functionality.

FL1000-SW

The FL1000 floor level palletizer provides an optimal price and speed combination for low speed applications. The FL1000’s compact footprint utilizes less than 60 square feet of floor space. Requiring no modification, the FL1000 can handle a wide variety of package types, including cases, trays, totes, film only and display packs from...

Dual Infeed

Columbia has perfected the dual lane palletizer concept. By splitting the infeed into two lanes, the speed that packages travel is halved as it approaches the palletizer, while the total throughput remains exceptionally high with stable row forming and package handling. This concept is also ideal for tall / high center of gravity product.

Dual Infeed

Columbia has perfected the dual lane palletizer concept. By splitting the infeed into two lanes, the speed that packages travel is halved as it approaches the palletizer, while the total throughput remains exceptionally high with stable row forming and package handling. This concept is also ideal for tall / high center of gravity product.

FL3000-R

Hybrid palletizers are a niche segment in material handling that combines the specific functionality of a robotic arm with the simple and robust layer forming capacity of a conventional palletizer. Although somewhat limited in scope, there are a few applications where combining the best of both worlds results in a fantastic solution.

FL3000-R

Hybrid palletizers are a niche segment in material handling that combines the specific functionality of a robotic arm with the simple and robust layer forming capacity of a conventional palletizer. Although somewhat limited in scope, there are a few applications where combining the best of both worlds results in a fantastic solution.

Servo Side Shift

Some palletizing applications can really benefit from the use of a side shift module on the palletizer infeed. Gently side shifting specific packages as part of the row forming process can increase the throughput of certain layer patterns on a given palletizer. The servo side shift from Columbia accomplishes this in a gentle and tunable fashion.

Servo Side Shift

Some palletizing applications can really benefit from the use of a side shift module on the palletizer infeed. Gently side shifting specific packages as part of the row forming process can increase the throughput of certain layer patterns on a given palletizer. The servo side shift from Columbia accomplishes this in a gentle and tunable fa...

HL Automatic Hoist Pins

The current generation of HL infeed palletizers started in 2013. It made sense to incorporate automatic hoist protection pins when updating the HL design. Previously available as an option, the pneumatically retained, spring actuated pins engage in staggered slots that are part of the palletizer frame when air pressure is removed from the palletizer.

HL Automatic Hoist Pins

The current generation of HL infeed palletizers started in 2013. It made sense to incorporate automatic hoist protection pins when updating the HL design. Previously available as an option, the pneumatically retained, spring actuated pins engage in staggered slots that are part of the palletizer frame when air pressure is removed from the p...

HL7200

The HL7200 incorporates the industry-leading safety package, ultimate flexibility and highest performance that is easy to operate. Requiring no modification, the HL7200 can handle a wide variety of package types including cases, display packs, totes, trays, bundles, shrink film only bundles, bales, plastic containers, crates, small cases and more. Maximum performance is found 24 hours a day, 7 days a week at up to 120 cases per minute (depending on pattern).

HL7200

The HL7200 incorporates the industry-leading safety package, ultimate flexibility and highest performance that is easy to operate. Requiring no modification, the HL7200 can handle a wide variety of package types including cases, display packs, totes, trays, bundles, shrink film only bundles, bales, plastic containers, crates, small cases an...

HL9200

The HL9200 provides the ultimate in safety, flexibility and performance. Flexibility starts with the easy to operate Product Manager HMI where the operator can create new patterns or modify existing patterns that will automatically adjust the programmable laner and smart squeeze technology to ensure gentle product handling and stable pallet loads. Ideal for multiline applications as zero time changeover is available to handle cases, display packs, totes, trays, bundles, shrink film without pad, bales, plastic containers, crates, small cases and more.

HL9200

The HL9200 provides the ultimate in safety, flexibility and performance. Flexibility starts with the easy to operate Product Manager HMI where the operator can create new patterns or modify existing patterns that will automatically adjust the programmable laner and smart squeeze technology to ensure gentle product handling and stable pallet...

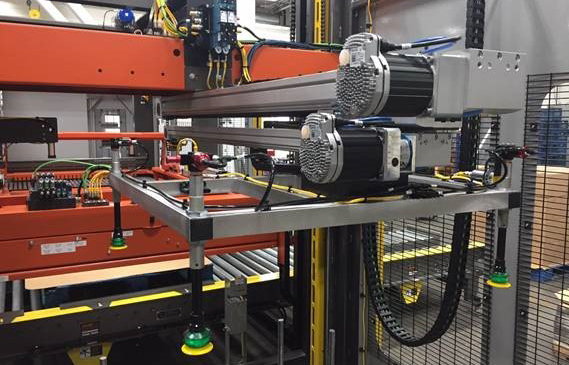

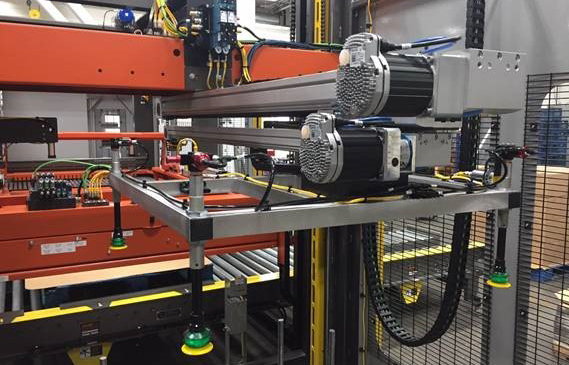

All Electric Palletizer

Most palletizers today are a combination of electric drives and pneumatic actuators. Some palletizing applications call for all electric actuation. When that is a requirement due to a sub zero freezer application, desire for reduced energy consumption or simply preference, Columbia Machine is able to accommodate.

All Electric Palletizer

Most palletizers today are a combination of electric drives and pneumatic actuators. Some palletizing applications call for all electric actuation. When that is a requirement due to a sub zero freezer application, desire for reduced energy consumption or simply preference, Columbia Machine is able to accommodate.

HL6200

The HL6200 is the fastest row forming palletizer in the industry. The HL6200 includes Columbia’s Category 3, Performance Level D safety system that utilizes Fortress trapped-key components, full height light curtains and a comprehensive guard package. Requiring no modification, the HL6200 can handle a wide variety of package types including cases, display packs, totes, trays, bundles, shrink film without pad, bales, plastic containers, crates, small cases and more. The HL6200 is capable of speeds up to 120 cases per minute (depending on pattern).

HL6200

The HL6200 is the fastest row forming palletizer in the industry. The HL6200 includes Columbia’s Category 3, Performance Level D safety system that utilizes Fortress trapped-key components, full height light curtains and a comprehensive guard package. Requiring no modification, the HL6200 can handle a wide variety of package types includi...

Columbia Machine PVT Eng Ltd (India)

Columbia Machine Engineering (India) is a wholly owned subsidiary of Columbia Machine Inc., USA. Headquartered in Vadodara India, CME is a recognized leader in the design and manufacturing of molds and machinery for the concrete products industry. CME manufactures, services and supports Columbia Machine palletizers throughout Asia, Africa and the Middle East.

Columbia Machine PVT Eng Ltd (India)

Columbia Machine Engineering (India) is a wholly owned subsidiary of Columbia Machine Inc., USA. Headquartered in Vadodara India, CME is a recognized leader in the design and manufacturing of molds and machinery for the concrete products industry. CME manufactures, services and supports Columbia Machine palletizers throughout Asia, Africa ...

FL6200

The FL6200 combines unmatched flexibility, zero-time changeover and the precision movements of a robot with the familiar simplicity of a conventional palletizer. Enhanced performance is achieved through the integration of servo technology. The FL6200 can handle a wide variety of package types including cases, display packs, totes, trays, bundles, shrink film without pad, bales, plastic containers, crates, small cases and more. The FL6200SW includes a fully integrated stretch wrapper for “stack-n-wrap” functionality.

FL6200

The FL6200 combines unmatched flexibility, zero-time changeover and the precision movements of a robot with the familiar simplicity of a conventional palletizer. Enhanced performance is achieved through the integration of servo technology. The FL6200 can handle a wide variety of package types including cases, display packs, totes, trays, bu...

Variable Position Turner (VPT)

Columbia’s patented Variable Position Turner (VPT) technology maximizes speed & flexibility for inline high speed palletizing. With Columbia’s VPT technology, servos are used to dynamically position the center turners laterally on an inline palletizer while the layer is being formed. VPT locations are accessed and programmed simply via the HMI.

Variable Position Turner (VPT)

Columbia’s patented Variable Position Turner (VPT) technology maximizes speed & flexibility for inline high speed palletizing. With Columbia’s VPT technology, servos are used to dynamically position the center turners laterally on an inline palletizer while the layer is being formed. VPT locations are accessed and programmed simpl...

Columbia Techmatik Poland

In February 2016, Columbia Machine announced its acquisition of Techmatik S.A. Headquartered in Radom, Poland. Techmatik is a recognized leader in the design and manufacturing of molds and machinery for the concrete products industry. Techmatik is now manufacturing, servicing and supporting Columbia Machine palletizers for the European market.

Columbia Techmatik Poland

In February 2016, Columbia Machine announced its acquisition of Techmatik S.A. Headquartered in Radom, Poland. Techmatik is a recognized leader in the design and manufacturing of molds and machinery for the concrete products industry. Techmatik is now manufacturing, servicing and supporting Columbia Machine palletizers for the European mar...

FL6200-SW

The FL6200 combines unmatched flexibility, zero-time changeover and the precision movements of a robot with the familiar simplicity of a conventional palletizer. Enhanced performance is achieved through the integration of servo technology. The FL6200 can handle a wide variety of package types including cases, display packs, totes, trays, bundles, shrink film without pad, bales, plastic containers, crates, small cases and more. The FL6200SW includes a fully integrated stretch wrapper for “stack-n-wrap” functionality.

FL6200-SW

The FL6200 combines unmatched flexibility, zero-time changeover and the precision movements of a robot with the familiar simplicity of a conventional palletizer. Enhanced performance is achieved through the integration of servo technology. The FL6200 can handle a wide variety of package types including cases, display packs, totes, trays...

MDR Pallet Conveyor

Columbia has developed a Motor Driven Roller (MDR) full load pallet conveyor suitable for handling loads up to 3,000 pounds. The MDRs are used in conjunction with roll to roll micro vee belt belts to allow for a low profile “chain box”, positive drive and close roller centers.

MDR Pallet Conveyor

Columbia has developed a Motor Driven Roller (MDR) full load pallet conveyor suitable for handling loads up to 3,000 pounds. The MDRs are used in conjunction with roll to roll micro vee belt belts to allow for a low profile “chain box”, positive drive and close roller centers.

Freezer Sheet Dispenser

The application of freezer sheets in palletizing is not new, but it has always been problematic. Columbia has engineered an innovative solution to allow typical freezer sheets to be placed between layers for palletized loads that require cooling. The Columbia solution is so flexible it even works with freezer sheets that have been used for numerous cycles.

Freezer Sheet Dispenser

The application of freezer sheets in palletizing is not new, but it has always been problematic. Columbia has engineered an innovative solution to allow typical freezer sheets to be placed between layers for palletized loads that require cooling. The Columbia solution is so flexible it even works with freezer sheets that have been used fo...

Servo Sheet Dispenser

Sheets on pallets and between layers is a common application. As expected palletizer throughputs continue to increase, the time allowed for placing sheets is reduced. Enter the servo actuated sheet dispenser head. The extremely fast and accurate travel speed of the sheet feeder carriage reduces the negative impact of tier sheet application, especially when sheets are required on every layer.

Servo Sheet Dispenser

Sheets on pallets and between layers is a common application. As expected palletizer throughputs continue to increase, the time allowed for placing sheets is reduced. Enter the servo actuated sheet dispenser head. The extremely fast and accurate travel speed of the sheet feeder carriage reduces the negative impact of tier sheet applicati...

Servo Soft Turn

Columbia started building the touchless turning Soft Turn unit almost 20 years ago. Columbia has supplied roughly 400 of these units and even retrofitted the Soft Turn on to competitors existing palletizers! The updated version allows for smaller gaps between packages, leading to increased palletizer throughput. Other enhancements have made the Soft Turn more flexible and able to handle smaller packages with ease.

Servo Soft Turn

Columbia started building the touchless turning Soft Turn unit almost 20 years ago. Columbia has supplied roughly 400 of these units and even retrofitted the Soft Turn on to competitors existing palletizers! The updated version allows for smaller gaps between packages, leading to increased palletizer throughput. Other enhancements have ma...

Smart Diagnostics

This option includes an industrial PC machine interface that takes the already advanced Product Manager software to the next level. Increased functionality includes enhanced graphics with real time sensor status and on machine location, video replay specifically tied to an error code in the event of a machine downtime occurrence and full functionality of manuals and video training materials.

Smart Diagnostics

This option includes an industrial PC machine interface that takes the already advanced Product Manager software to the next level. Increased functionality includes enhanced graphics with real time sensor status and on machine location, video replay specifically tied to an error code in the event of a machine downtime occurrence and full f...

Servo Bump Turn

The new Servo actuated turn assist is yet another example of innovation and flexibility. The stroke of the turn shoe is programmable via the HMI to allow for adjusting the turning action for different sized packages. It is extremely fast acting, allowing for gaps to be reduced from package to package to help increase throughput. The pneumatic cushioning is also adjustable for different weight packages and very responsive to aid in protecting the integrity of delicate product.

Servo Bump Turn

The new Servo actuated turn assist is yet another example of innovation and flexibility. The stroke of the turn shoe is programmable via the HMI to allow for adjusting the turning action for different sized packages. It is extremely fast acting, allowing for gaps to be reduced from package to package to help increase throughput. The pneumat...

HL4200

The HL4200 high level palletizer includes a VFD-controlled pacer meter belt, bi-parting apron and Product Manager HMI Graphic interface. These features, combined with the ability to form “layer gaps” side-to-side and front-to-back, make the HL4200 extremely flexible. The HL4200 can handle a wide variety of package types including cases, display packs, totes, trays, bundles, shrink film without pad, crates, small cases and more.

HL4200

The HL4200 high level palletizer includes a VFD-controlled pacer meter belt, bi-parting apron and Product Manager HMI Graphic interface. These features, combined with the ability to form “layer gaps” side-to-side and front-to-back, make the HL4200 extremely flexible. The HL4200 can handle a wide variety of package types including cases,...

Columbia Machine Do Brasil

For over 40 years Columbia Machine has been active in Brazil with a substantial machine base located throughout the country. The incorporation of Columbia Machine do Brasil (CMB) and the 2019 acquisition of Vibramolde, a leading Brazilian mold supplier, gives the company the base to support customers locally and throughout South America. Located just outside São Paulo, CMB is central to the majority of Columbia’s customers in Brazil.

Columbia Machine Do Brasil

For over 40 years Columbia Machine has been active in Brazil with a substantial machine base located throughout the country. The incorporation of Columbia Machine do Brasil (CMB) and the 2019 acquisition of Vibramolde, a leading Brazilian mold supplier, gives the company the base to support customers locally and throughout South America. ...

HL2200

The HL2200 high level palletizer offers users a compact footprint and high performance. Standard features include a VFD controlled bi-parting layer apron and Columbia’s state-of-the-art Product Manager controls package. These features, combined with the ability to form “layer gaps” side-to-side and front-to-back, make the HL2200 extremely flexible. The HL2200 can handle a wide variety of package types, including cases, display packs, totes, trays, bundles, shrink film without pad, crates, small cases and more. When equipped with optional small case handling components, the HL2200 is ideally suited to palletize very tall and narrow product, even with a high center of gravity.

HL2200

The HL2200 high level palletizer offers users a compact footprint and high performance. Standard features include a VFD controlled bi-parting layer apron and Columbia’s state-of-the-art Product Manager controls package. These features, combined with the ability to form “layer gaps” side-to-side and front-to-back, make the HL2200 extre...

Diagonal Acting Side Shift (DASS)

The Diagonal Acting Side Shift (DASS) design allows cases to be diverted from the product flow without changing the gapping between packages. The forward speed of each package remains constant, which allows for greater pattern forming flexibility and higher throughput than the previous designs. Along with the speed enhancement, the DASS unit is also easier to program layer patterns and provides more gentle handling for fragile products, when needed.

Diagonal Acting Side Shift (DASS)

The Diagonal Acting Side Shift (DASS) design allows cases to be diverted from the product flow without changing the gapping between packages. The forward speed of each package remains constant, which allows for greater pattern forming flexibility and higher throughput than the previous designs. Along with the speed enhancement, the DA...

RFID Reader For Product Manager Login

RFID employee badge reader for automatic HMI log in. Includes up to 5 levels of HMI access from basic operator interface all the way up to full access to Product Manager and detailed machine settings.

RFID Reader For Product Manager Login

RFID employee badge reader for automatic HMI log in. Includes up to 5 levels of HMI access from basic operator interface all the way up to full access to Product Manager and detailed machine settings.

Star Wheel Turner

Columbia’s servo actuated Star Wheel Turner is ideal for applications where very small, high CG or just difficult to handle products are being palletized.

Star Wheel Turner

Columbia’s servo actuated Star Wheel Turner is ideal for applications where very small, high CG or just difficult to handle products are being palletized.

Double Stacker

Columbia’s Fork Style Load Double Stacker is designed to stack a complete pallet load of product on top of another load.

Double Stacker

Columbia’s Fork Style Load Double Stacker is designed to stack a complete pallet load of product on top of another load.

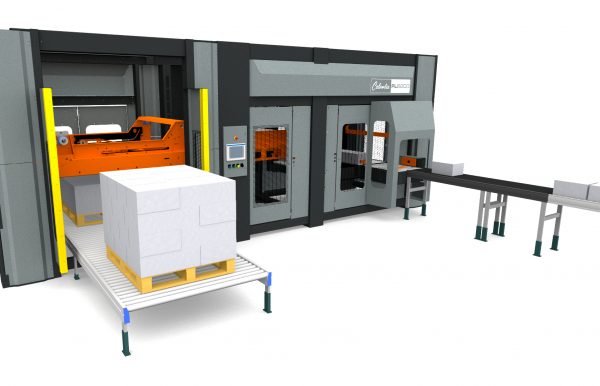

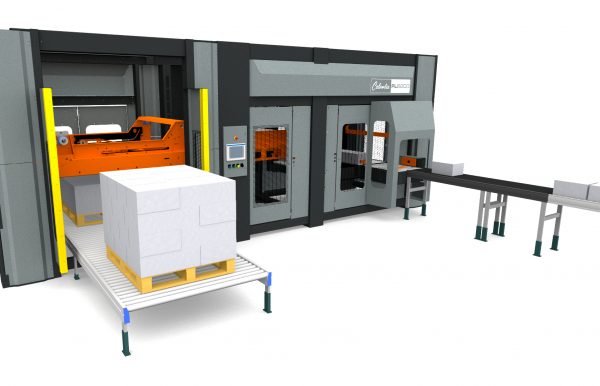

FLD2500

The new FLD2500 palletizer is the latest design from Columbia Machine. This ultra-compact palletizer can be equipped with a fully integrated stretch wrapper that allows for concurrent “stack and wrap” load building.

FLD2500

The new FLD2500 palletizer is the latest design from Columbia Machine. This ultra-compact palletizer can be equipped with a fully integrated stretch wrapper that allows for concurrent “stack and wrap” load building.

FLD2500-SW

The FLD2500-SW has an extremely compact footprint and simultaneously stacks and stretch-wraps a variety of package types including cases, trays, shrink bundles, display packs and more.

FLD2500-SW

The FLD2500-SW has an extremely compact footprint and simultaneously stacks and stretch-wraps a variety of package types including cases, trays, shrink bundles, display packs and more.